Company Insight

Sponsored by Datwyler

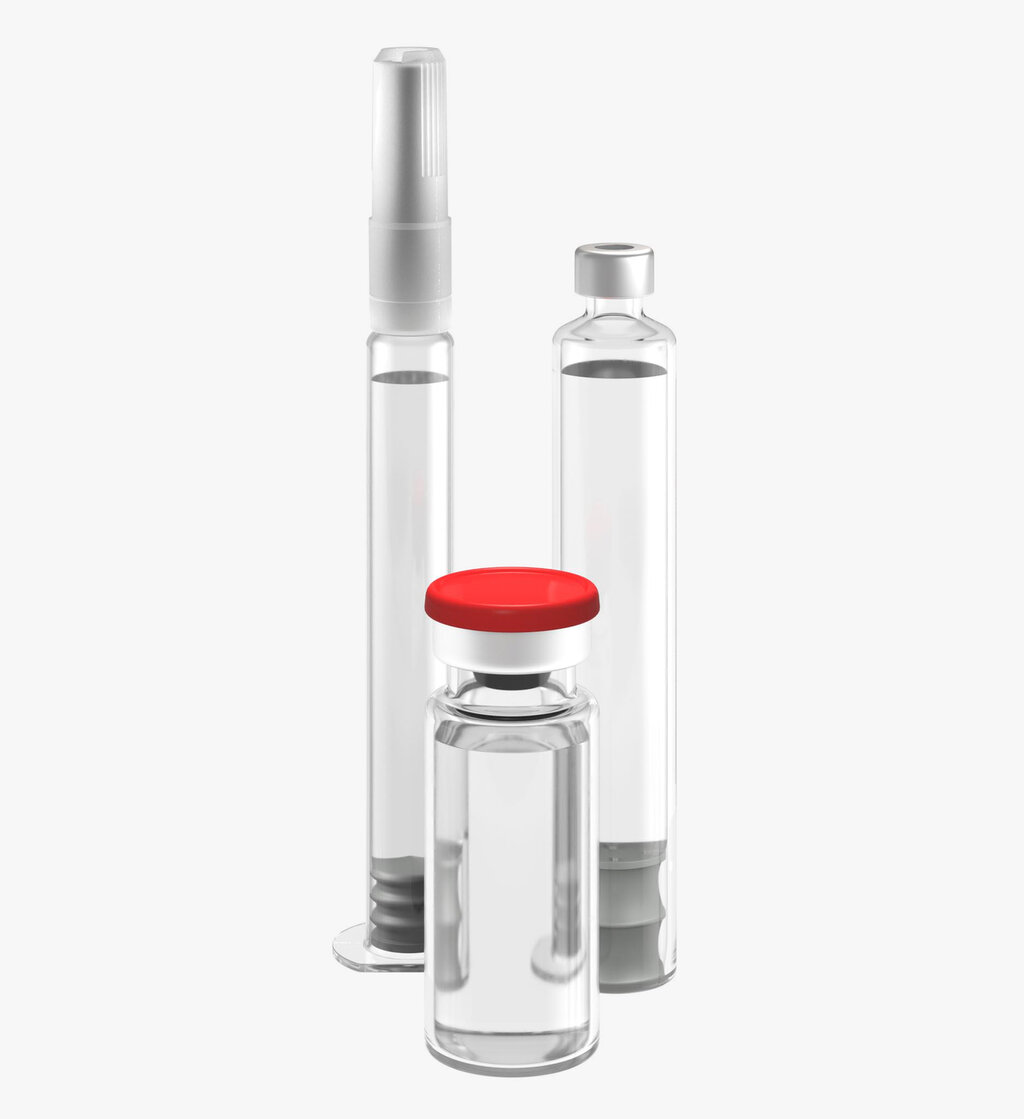

Developing Breakthrough Medicine Is Hard Enough, Choosing A Drug Packager Shouldn’t Be

In recent years, medical emergencies have pushed the need for advancement in biopharma. This demand has introduced new regulations large and small biopharma organizations must adhere to remain sustainable and innovative. It is for these reasons that we understand that pharma executives and decision-makers must partner with trustworthy individuals and companies that have shared values in the interest of improving patient outcomes. One such need: securing high-quality pharmaceutical packaging solutions.

Datwyler, a premium pharma packaging company, has “perfected” the process of choosing quality packaging for injectable drugs. As a drug manufacturer, you deserve a partner that alleviates the burden of evaluating and assessing drug packaging. Developing the next breakthrough medicine is too important a task to put in the hands of packaging providers who aren’t equipped to protect its efficacy.

Through its evaluation process and checklist, Datwyler helps you assess the presence of foreign materials and how to ensure you meet the standards for distribution and marketability. From Particulates, to Extractables and leachables, Regulations, Functionality, Engineering capabilities, Container closure integrity, and Total quality, the “PERFECT” process serves to guidance on the most important aspects of component selection:

- Particles – The presence of foreign matter, such as fibers, on or in a component set to be used with a drug product.

- Extractables and Leachables – The migration of substances from a packaging component into a drug product.

- Regulations – Consideration of the regulatory environment in which a drug product will be marketed. As different regions have different regulations, being aware of and complying with regional regulatory bodies is a prerequisite for marketing drug products.

- Functionality – Different for every type of product, functionality may include qualities such as break-loose and glide forces, stopper pop-up, ability to perform in certain storage conditions, and more. Typically, functionality assesses the complete packaging system.

- Engineering Capabilities – Similar to machinability, this criteria analyzes the compatibility between a company’s’ fill-finish lines and the component in question.

- Container Closure Integrity – The prevention of migration of product into or out of a system through ensuring dimensional compatibility of the components within that system.

- Total Quality – An analysis of the quality needs of a given project, and the capabilities achieved by a given product or process. This can encompass wash processes, sterilization, defect limits, particulate levels, compliance testing, vision inspection systems, and more.

For a more in-depth analysis of what to consider in your drug packaging selection process, download the “Successfully Analyze Your Packaging Needs,” whitepaper now.

About Datwyler

Datwyler focuses on high-quality, system-critical elastomer components and has leading positions in attractive global markets such as healthcare, mobility, general industry, and food & beverage. With its recognized core competencies and technological leadership, the company delivers added value to customers in the markets served. With more than 20 operating companies, sales in over 100 countries, and more than 7,000 employees Datwyler generates annual sales of more than $1,000 million. Within the healthcare solutions business area, Datwyler develops, designs, and manufactures solutions for injectable packaging and drug delivery systems to facilitate customers to create a safer medical environment of tomorrow. Looking back on more than 100 years of history, Datwyler is a reliable partner, now and in the future!