Did you know that every second single-use contact lens is sterilized with an autoclave from Schoeller Bleckmann Medizintechnik (SBM)? With countless projects around the world, over 50 years of experience and more than 15 years within the Syntegon group, SBM is the ideal partner when it comes to pharmaceutical sterilization and freeze-drying processes. The vast portfolio includes customer-specific solutions for the terminal sterilization of medical products and equipment, as well as freeze dryers with loading and unloading systems.

SBM: the sterilization and freeze-drying expert

Sterilizing pharmaceutical products and equipment

Reproducible terminal sterilization of medical products and equipment is at the core of SBM’s portfolio. SBM offers all the industry’s most common and preferred methods. From vacuum-steam to steam/air mixture and hot water shower processes, the versatile autoclaves ensure an effective treatment of porous loads and liquids in open, semi-sealed, or closed containers. Combined systems even incorporate multiple processes within a single sterilizer, offering much greater flexibility in terminal sterilization while optimizing energy requirements and ensuring maximum safety throughout the process.

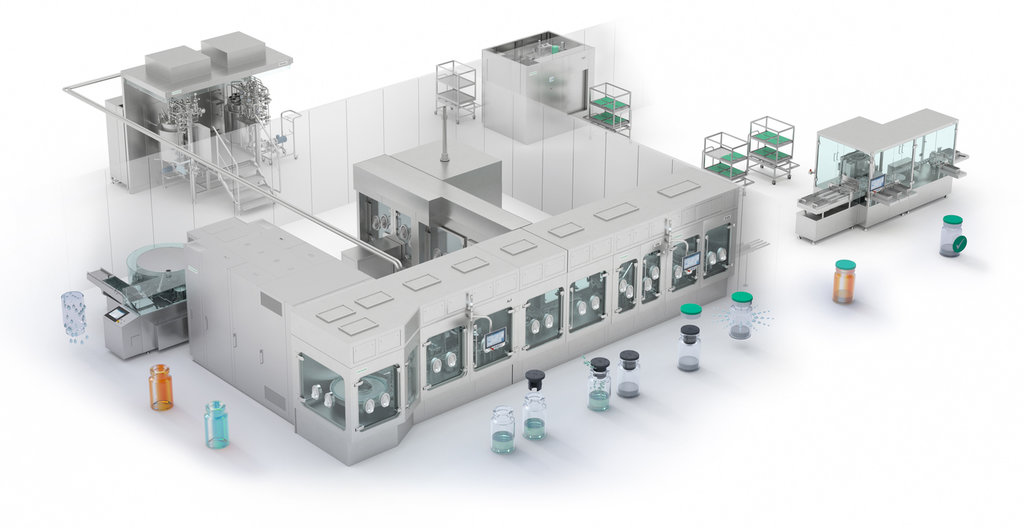

Freeze drying for temperature-sensitive products

When it comes to freeze-drying, the highly scalable SBM system ensures the lyophilization of thermolabile products, such as oncological medicines, vaccines, or antibodies. The modular concept perfectly adapts to the respective working environment and can be fully integrated into an entire range of GMP-compliant machines. Moreover, the patented loading/unloading system provides safe and efficient processes while saving a considerable amount of space.