COMPANY INSIGHT

Sponsored by L.B. Bohle

Dry granulation – continuous

and efficient

Granulation is an important process step in the manufacturing of pharmaceutical products. The goal is to take fine, non-compactable powders and turn them into coarser agglomerates that can then be pressed into tablets. Granules may be used directly as pharmaceuticals or serve as an intermediate product in the tablet manufacturing.

Tablets are the most commonly used form of drug delivery as they are not only easy to produce but can also be produced in large quantities.

Dry granulation, which unlike wet granulation is a continuous process, is an established procedure in the production of pharmaceutical solids. It is employed not only for products that are sensitive to moisture or temperature, but also for its cost advantages.

In comparison to wet granulation, no energy-intensive drying processes are needed. This saves a major investment in equipment and production space and leads to a lower cost per lot thanks to the savings in energy cost. Without a drying step, it becomes superfluous to stock up on, distill and dispose of industrial solvents.

Bohle dry granulators guarantee a compacting process with a high material throughput of up to 400 kg/h. This allows different products and lot sizes to be produced with one machine.

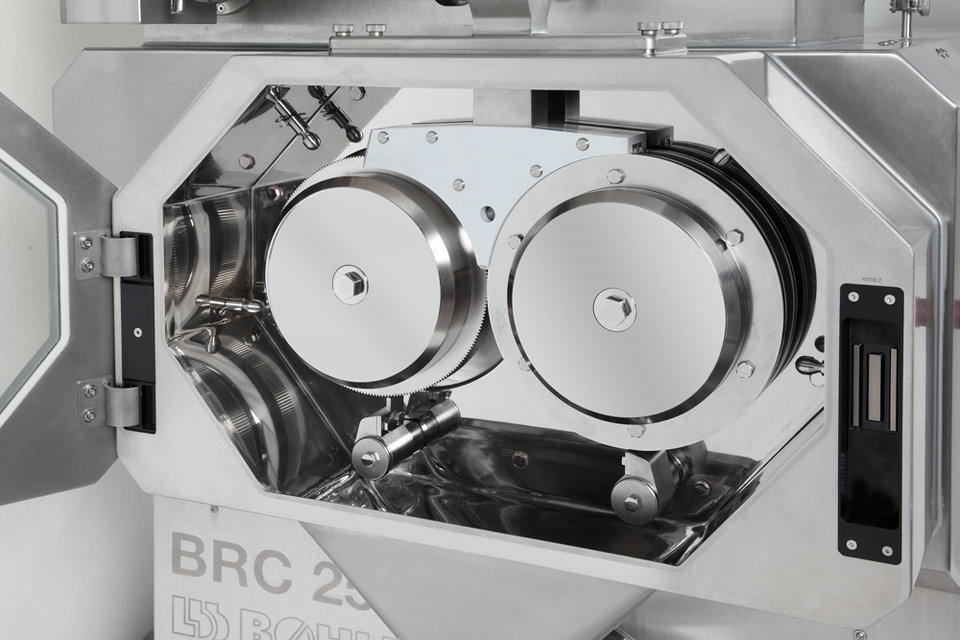

Horizontal roller configuration with benefits

Dry granulators are differentiated based on their roller configuration. There are granulators with rollers configured horizontally, vertically and diagonally.

L.B. Bohle focuses on horizontally configured rollers in the compacting process. Among the advantages of this configuration are a better de-aeration of the screws and a shorter discharge route for the slugs. In addition, dry granulators vary in terms of width, diameter and surface characteristics of the rollers.

The space between the rollers is divided into three zones. A pre-compaction of the particles takes place in the slip region (feeding zone). The main compaction of the particles takes place in the compaction zone; depending on the material in use, this can take place through particle deformation or particle fragmentation. The material release (extrusion) takes place in the third zone.

Another distinction between systems concerns the variability of the space between the rollers. Dry granulators with a variable gap are preferable as only they can ensure a consistent granule porosity at a constant compaction pressure, thereby guaranteeing reproducible production conditions for slugs. During the continuous monitoring of the process, a reference value comparing actual and target gap size is generated. The goal is to maintain a parallel gap between the rollers so that the slugs exiting the process exhibit identical characteristics throughout the entire lot.

The rotation of the feeding screw is in a control loop with the gap adjustment. This means that as the gap widens, less material is fed into the gap by the feeding screw so that the gap will close again. Due to this automated feedback control, the slugs are produced with a defined thickness and porosity.

With the BRC series, Bohle combines high production capacity with minimal material loss. Drive generation occurs purely electromechanically, in contrast to the competitors’ models. This ensures consistent slug characteristics. An electromechanical drive system avoids the disadvantages of hydraulic pressure regulation such as the need to replace old oil and valves, temperature excursions and contamination of the oil. This highly precise process is supported by the incorporation of pressure sensors located directly at the site of energy transfer and thereby capable of measuring the pressure directly. The results are more accurate than in hydraulic arrangements, whereby pressure values are generally arrived through calculation.

The BRC regulates the compaction energy and slug thickness in an innovative way and generates a consistent compacting of the material throughout a range of < 1 - 400 kg/h. Meanwhile, the advanced design of the unit simplifies handling and shortens the fitting procedure.

The “Hygenic Design” and already as standard integrated washing nozzles guarantee an effective WIP process with a residue-free removal of the product. The compactor also meets “Quality by Design” requirements with its functional GMP-tailored construction and the option of implementing PAT-tools.

Besides influencing the compacting energy of the unit, the milling step has a substantial impact on the particle size of the granule. Milling the slugs into a granule with the desired range of particle dimensions is performed by the conical Bohle Conical Mill (BTS) and sieve inserts with very little waste – even at a high throughput rate. Every BRC can be re-fitted in a matter of minutes to serve as an alternative rotational sieve and adapted flexibly to the process and slug conditions.

An important and substantial advantage of roller compactors is their small footprint and easy integration into the production process. Bohle has installed numerous BRC units in various production scenarios (stand-alone unit, wall installments, stage and multi-floor applications as well as individual containment applications) working with both batch and continuous manufacturing concepts.