Your Partner for Force and Torque Testing Equipment

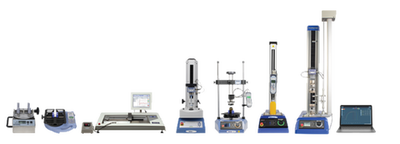

Mecmesin, established in 1977, is a leading designer and manufacturer of tensile testers and torque measuring equipment. We offer a full range of precision test systems and instruments that are accurate, reliable and excellent value for money.

Operating under ISO 9001 quality standards, Mecmesin test solutions are used to guarantee the quality of components, materials and finished products, from factory floor through to the R&D laboratory – across all industries in the pharmaceuticals sector.

Backed up by IQ, OQ and PQ document templates to support you in your process validation activities.

Our products enable you to perform checks to ensure:

- Conformance to standards

- Optimised design

- Efficient production

- Minimum wastage

- Cost savings

- Quality

Find out more about our test applications in:

- Medical devices and components

- Pharma products and raw materials

- Packaging systems; CRCs and sterile

Dedicated test systems for specific industries

Our software shows clear results of your test

Precision equipment for delicate products

Materials testing with intuitive software

Torque testing solutions for the pharma lab

scroll down

Medical devices and components testing

Quality and reliability is key in a highly regulated environment, where patient safety is critical.

watch the video

Assembly, removal, operational and disassembly efforts can all be measured to protect and enhance brand reputation:

- Luer design taper connector torque

- Syringe glide forces

- Biopsy injector trigger force

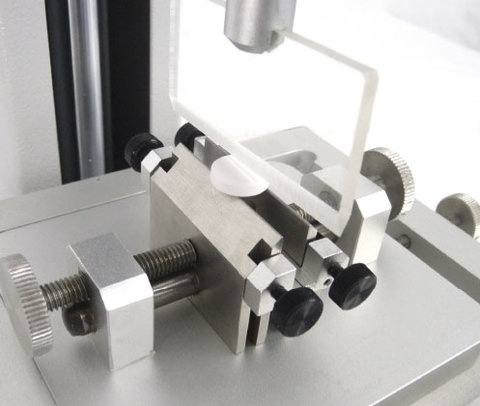

- Tubing pull-out resistance

- Needle strength, lancet retention

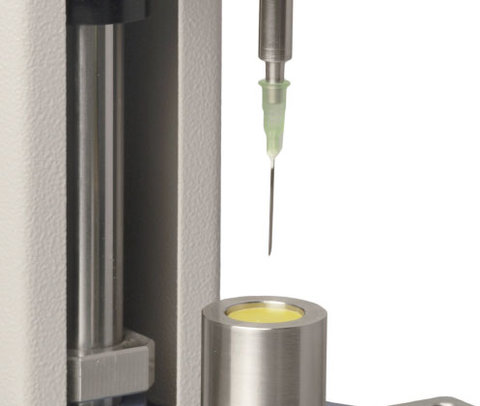

- Elastomeric closure puncture

Dispensing mechanisms built into closures or actuation components in dosage devices can be evaluated for security and ease-of-use:

- Pump and spray compression force

- Drug delivery dial precision torque

Mecmesin equipment securely clamps these types of components for repeatable testing and our range of loadcells accurately measure the wide range of loads involved.

Biopsy injector trigger force test

Pull-out testing on connector designs

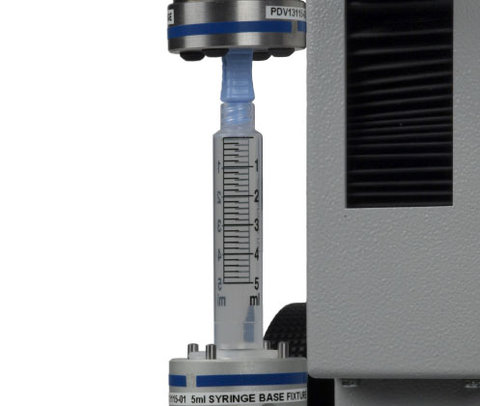

Syringe glide force testing

Rotational effort for dosage pen

Luer connector assembly torque to turn

Insulin pen operational torque tester

scroll down

Pharma products and raw materials testing

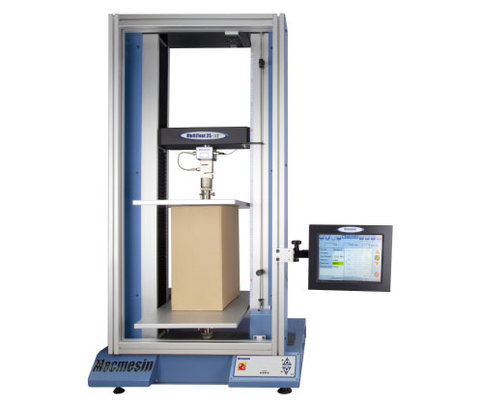

Our range of OmniTestTM Universal Testing Machines enable the raw materials for packaging, products and components to be accurately characterised in tension and compression, up to 50 kN.

Mecmesin’s VectorProTM software is designed to help facilitate meeting FDA 21 CFR Part 11 requirements, with its database architecture and strict operator permissions features.

Extensometer connectivity and a comprehensive suite of materials testing calculations are included:

- Ultimate tensile strength (UTS)

- Stress and strain at break

- Young’s Modulus

- Yield and 0.2% offset yield

- 3 and 4-point flexural modulus

We can test the physical properties of solid and semi-solid samples to evaluate the impact of different ingredient formulations on manufacturing processing parameters and product texture:

- Aspiration and evacuation syringeability

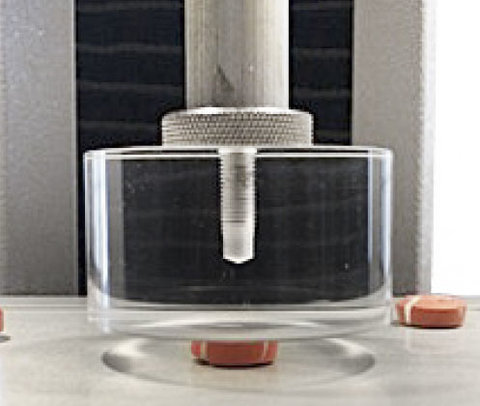

- Cream and gel consistency and flow

- Capsule burst resistance

- Tablet hardness crush, snap

- Gel strength

Gel Bloom Strength testing

Stress-strain characterisation of raw materials

High-strength materials testing capacity

Tablet crush testing

Tablet hardness snap testing

Accurate instrumentation for elongation measurement

Packaging systems testing including CRCs and sterile

If you manufacture or supply primary, secondary or tertiary (transit) packaging, you need accurate and reliable testing systems to apply stringent industry standard test methods:

- Openability – peel and tear

- Sharps container puncture resistance

- Strength - top-loading and crush

- Labelling - adhesion and friction

Closure torque testing involves a range of tests for events designed into screw caps and unthreaded stoppers.

This includes the torque to remove or apply the closure and also the measurement of the effort required to overcome safety features:

- Child-Resistant Closures (CRC)

- Evaluate push and twist designs

- Breach tamper-evident features

Mecmesin’s versatile motor-driven testing equipment ensures constant rotational speed control for ultimate repeatability and accuracy. Our fixtures hold flexible specimens without affecting the results.

Transit packaging box crush test

Computer-controlled motor-driven closure tester

Digital cap tester designed for pharma labs

Sharps bin material penetration resistance

Actuation force of a pump dispenser

Easy-to-use manually operated closure tester

Child Resistant Closures need specialised testers

USP testing of elastomeric closure

Highly accurate sterile packaging peel testing

Contact us for a quote or demo:

Web: www.Mecmesin.com

Phone: +44 (0) 1403 799979

Email: info@mecmesin.com