Company Insight

Sponsored by Alphial

Alphial - Your Trusted Partner for Pharmaceutical Primary Packaging

ALPHIAL specializes in manufacturing tubing glass ampoules and vials, and since 2021, we have expanded our offerings to include RTU (Ready-to-Use) and pre-washed vials. With five advanced manufacturing facilities and 70 production lines, ALPHIAL has a total annual production capacity exceeding 1 billion pieces.

Main image: Glass ampoules - Production.

Alphial S.r.l. is a leading tubular glass converting company that manufactures ampoules and vials for the pharmaceutical market.

Formed from the merger of industry leaders SM Pack and Crestani, Alphial expanded in 2024 with the acquisition of SICATEF and Luxenia, two Italian companies specializing in tubing glass ampoules. The company now employs over 220 people across five manufacturing sites.

Our commitment to product quality, expanding production capacity, and strong presence in major international markets make Alphial a globally recognized, reliable, and solid partner.

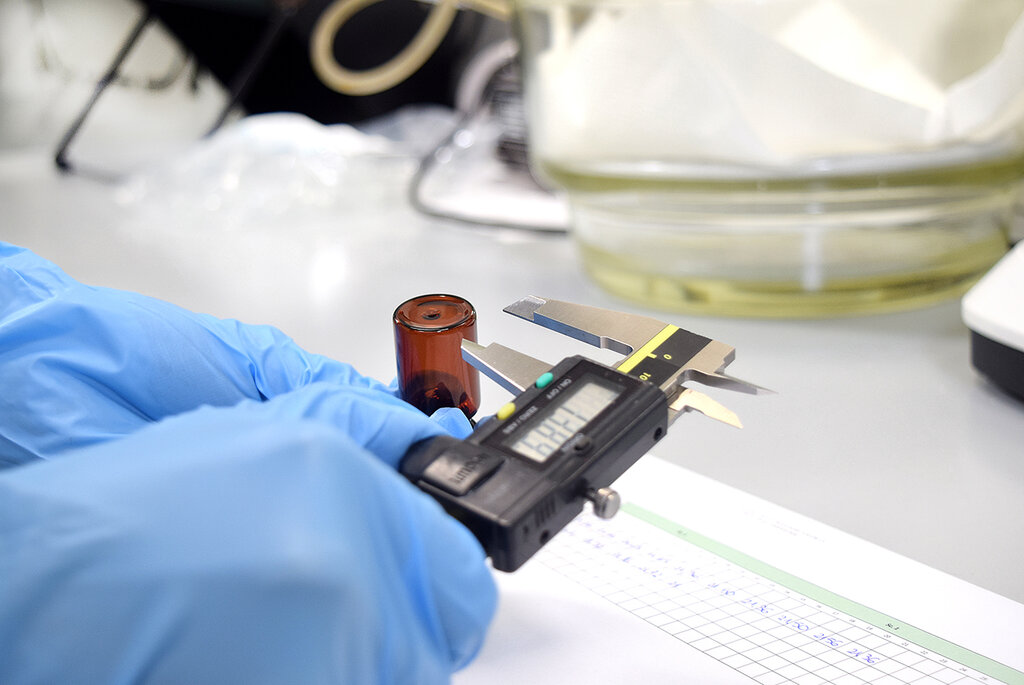

We utilize state-of-the-art inspection systems that are continually updated to ensure the highest quality of our ampoules and vials. These systems are the cornerstone of our commitment to maintaining consistent quality and high product reliability for our customers.

Alphial’s competitive advantage and brand recognition are driven by our superior product quality, steadfast commitment to research and development, expanding production capacity, and strong presence in international markets.

Glass vials - Quality control.

Our objectives are clear and straightforward:

To ensure the highest product quality.

To support our customers at every stage, from initial project planning to refining technical and aesthetic details.

To minimize the environmental impact of our production by significantly reducing waste.

Our activities are customer-centric, focusing on enhancing our service offerings while respecting the environment. With the support of our suppliers, we select the finest raw materials, leading to direct improvements in product quality. This commitment requires ongoing investments in finances, logistics, and skills.

We advocate for the use of glass as an eco-friendly and recyclable material, encouraging our customers to make sustainable choices. We believe that environmental pollution is not solely about plastic; the sustainability of all materials, including glass, depends on mindful daily actions.

RTU glass vials - LS5 washing process.

The production facilities in Sandrigo (VI), Bernareggio (MB), Treviglio (BG), and Perugia (PG) are dedicated to converting tubular glass into ampoules. Combined with the HQ equipment in Felino (PR) for vial production, Alphial operates 70 production lines, achieving an annual capacity of over 1 billion ampoules and 70 million vials. Alphial sells in over 100 countries through a combination of direct sales, commercial agencies, and distributors.

All our manufacturing sites are ISO 9001 and ISO 15378 certified. Additionally, we hold DMFs for China, the US, and Canada.

Tubing glass vials are produced at Alphial’s headquarters in Felino (Parma, Italy), where we also offer sterilization and depyrogenation services for glass packaging, including those not manufactured in-house, using a process known as LS5.

Our state-of-the-art facility features a continually evolving lineup of machines and a pharmaceutical department capable of processing up to 200,000 pieces per day in a controlled environment, meeting LAF per ISO 5 – Class A standards. Inside our Clean Room, advanced robotic systems minimize human contact with the product, ensuring precision, consistency, and reduced industrial costs.

The Clean Room is equipped with a comprehensive chemical and microbiological laboratory, providing top-level monitoring services for quality and environmental safety. Our entire production facility is ISO 15378 certified, demonstrating our commitment to maintaining the highest industry standards.