COMPANY INSIGHT

Sponsored by Molnár-Institute

How to Manage Analytical Methods Across all Stages of their Lifecycle Using One Chromatographic Modeling Tool

By:

Imre Molnár, PhDFounder and President Molnár-Institute for Applied Chromatography

Hans-Jürgen Rieger, PhDVice President, Product Management Molnár-Institute for Applied Chromatography

Dek: visual chromatography modeling and optimization software

Chromatographic modeling using DryLab®4 software from Molnár-Institute saves time and resources across all three stages of the lifecycle of an analytical method. Method run time can easily be reduced 40-fold with improved selectivity when redesigning an old method, simultaneously reducing the development time by a factor of 12. US Pharmacopeia (USP) methods that frequently fail can be fixed in accordance with allowed changes (USP 621) using DryLab4. Chromatographic modeling can safeguard method robustness across the lifecycle for compendial methods, method development, and method transfers.

Lifecycle management of analytical methods

The lifecycle of analytical methods has three stages: Design, Qualification, and Continued Verification. Ideally, a design space is defined during the early stages of the method development. Methods design is a range of parameters within which the method performs as intended and within which the method is fit for use. ICH Q8(R2) states that “working within the design space is not considered as a change.” In addition, ICH Q12 (draft) introduces a post-approval management plan to be initiated at submission (Post-Approval Change Management Protocol or PACMP). It integrates flexibility and lowers the need for new validation when changes are made to the method in Stage 3 (i.e., continued verification).

When one runs into problems with a method in Stage 3, it may be necessary to return to design and development (Stage 1) to resolve the problems. This task can be an arduous one, especially when production is ongoing. Indeed, one department typically handles both Stage 1 method development and design, while the Stage 3 routine method use is handled by a different department, with tight timelines for production of results.

DryLab4 software from Molnár Institute can help with this challenge because it can optimize the performance of an existing method in three simple steps: input runs, peak tracking and create the model, which helps find the most robust separation within the existing design space. The input runs bracket the existing method conditions about the allowed variations for the multiple variables of the method. Peak tracking is the identification of peaks in the input runs. DryLab then creates the model.

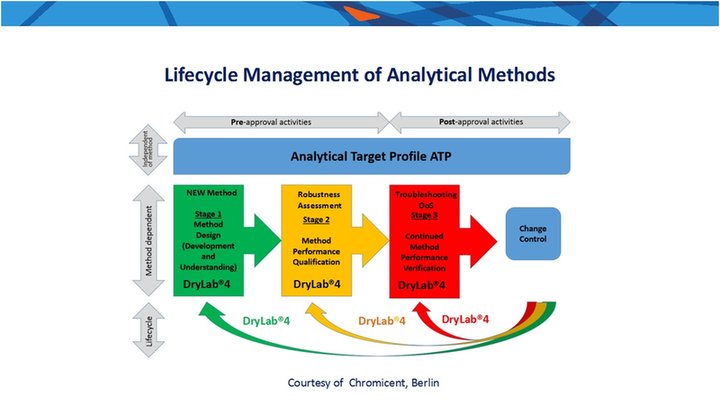

Using just a few experimental runs, DryLab visualizes the chromatographic process interactively, running hundreds of simulations in a few moments to find the best separation conditions, highest critical resolution, shortest run time and the highest robustness. Furthermore, evaluating method robustness during method development, while defining the analytical target profile (ATP), ensures a working design space for post-approval management and flexibility in dealing with out of specification (OoS) results in routine work. DryLab can be used at all stages, as shown in Figure 1/Slide 6.

Figure 1. Lifecycle Management of Analytical Methods, showing DryLab should be used in all phases to enhance a better chromatographic method understanding.

Case study 1: ebastine

Compendial methods are Stage 3 methods by definition and do not require further method development and validation. However, in some cases, the method may need to be modernized. Such was the case with ebastine from a description in the European Pharmacopeia. The method was not fit for purpose because it was too long. The analytical work could not keep up with production. DryLab was used to reduce the analysis time from 160 minutes to less than 3 minutes in less than two weeks.

Based on prior knowledge and experience with similar projects, the parameters: gradient time tG (3-9 min), pH (2-3), temperature T (15-45°C), and ternary composition of the eluent B were considered the most probable potentially critical separation parameters for the method. DryLab also produced the Knowledge Management Document, complete with the original chromatograms, peak tracking, resolution maps, robustness testing, and confirmation of predictions. This improved method was accepted in five countries and is described in literature.

Case study 2: amlodipine

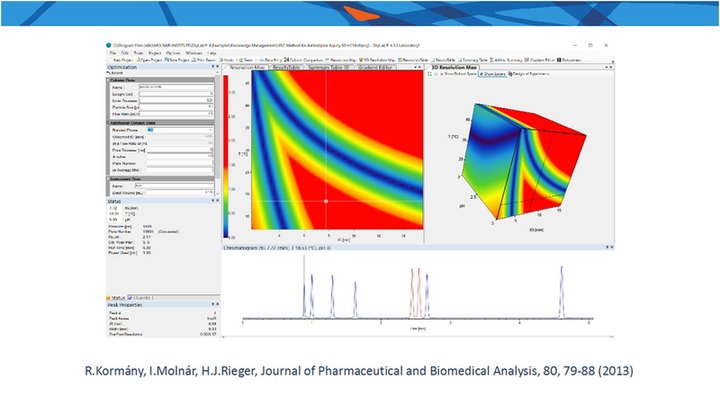

In another case, the routine method for amlodipine in the European Pharmacopeia was found to be not fit for purpose (Slide 18). Not only was it a long 45–60-minute isocratic method, but it also had coelutions and peak turnovers. Again, using only 12 experimental runs, and calculation of the model as shown in Fig.2, it became clear, that the separation in the middle group of 3 peaks was not based on pH-changes, but much more based on temperature fluctuations and had to do also with the gradient time selection.

Figure 2. DryLab model of Amlodipine. The original EuPharm method could be reduced from 50 min to less than 6 min and the chromatographic understanding could be improved.

The model enabled researchers to evaluate the resolution and robustness across the range of critical separation parameters. Us pharmacopeia <621> states, “multiple adjustments can have a cumulative effect on the performance of the system and are to be considered carefully before implementation.” using drylab to troubleshoot and understand the method does this using a virtual model that combines the multiple parameters in a 3d cube.

In figure 2, the cross-hatch is set to the optimum area. However, when the user moves the cross-hatch around different areas of the cube, the chromatogram shows the predicted result as a chromatogram. The red area indicates areas of robustness. The gradient of color strips from orange to deep blue show how the critical resolution as the most important method parameter most likely to result in method failure and oos results. Working near the boundary of the red zone results in poor method robustness. The critical pair for resolution is shown in red. As method parameters change, the critical peak pair may change also, which is reflected in the virtual chromatogram in the model. Drylab makes it very straightforward to take advantage of modern ultrahigh performance liquid chromatography equipment and to optimize a robust method with a less than six-minute run time.

Using drylab to safeguard method robustness

Building robustness into the method as early as possible in method development will help safeguard against later OoS results. A method is robust if it remains unaffected by small but deliberate variations in method parameters. A robust method provides reliability when used in normal daily work with multiple operators, multiple instruments, and slight changes in columns from batch to batch. This was not often done in the past, perhaps because of the complexity of designing an experimental matrix that takes into consideration the cumulative effect of multiple factors. If the intended purpose of the method is quantification, then the first requirement for robustness is good resolution. The value of the critical resolution should be at least 1.5 ( = baseline resolution). A critical resolution of 2 for the critical pair is even better. Good resolution means one has a baseline separated chromatogram, which means one can more reliably integrate and quantify the peaks.

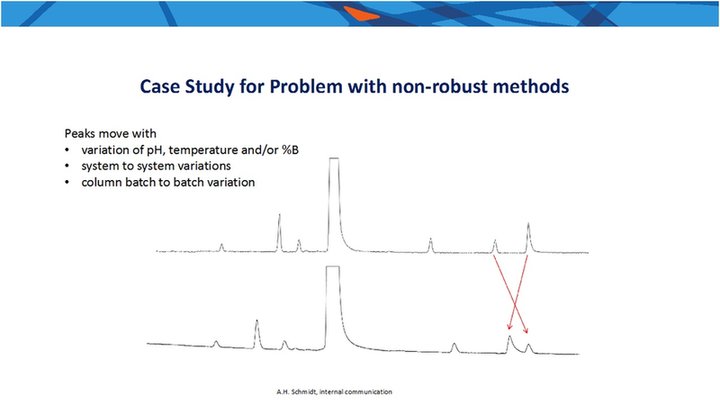

Pramipexole is a drug substance used to treat Parkinson’s disease or restless leg syndrome. The separation of pramipexole from its known impurities is described in the European Pharmacopeia as well as in the US Pharmacopeia. The method calls for a C18 stationary phase; recommended columns are Inertsil or Symmetry. The mobile phase is a pH 3 phosphate buffer with an ion pair reagent. The organic eluent is acetonitrile and the gradient range is from 20–40%B in 15 minutes at a temperature of 40°C. This method was used in the laboratory for a long time, but reliability has since declined, as shown in Figure 3/Slide 22.

Figure 3. Separation of Pramipexol and its impurities. The last 2 peaks did often change their positions causing Out of Specifications (OoS) results.

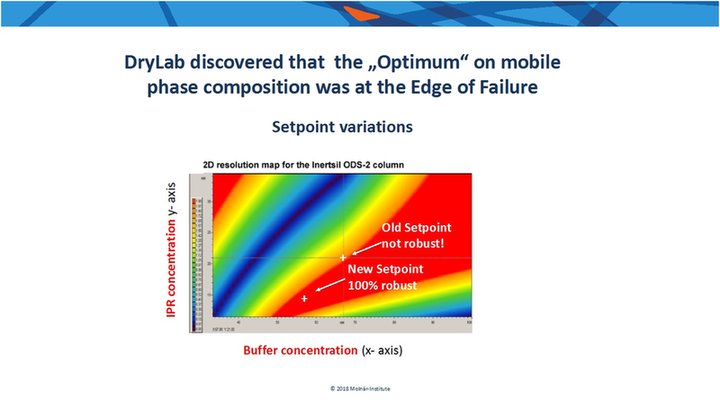

Thus, researchers wanted to adjust the method to improve the robustness and to comply again with the system suitability testing. DryLab was used to create a model about the design space for the conditions observed in the official method to see if they were still at the optimum working point. Researchers ran 12 experiments across the range of the official method with the combinations of gradient times of 8 minutes, 16 minutes, and 24 minutes; pH values of slightly higher than 3.3, and slightly lower than 3; and temperatures of 27 °C, 40 °C, and 54 °C. Data were then imported into DryLab, which helped with peak tracking. DryLab then calculated the model and used the input data to run hundreds of virtual experiments to create the model and generate the resolution map (see Figure 4/Slide 27).

Figure 4. With DryLab the setpoint of the method can be altered without the need for a new validation.

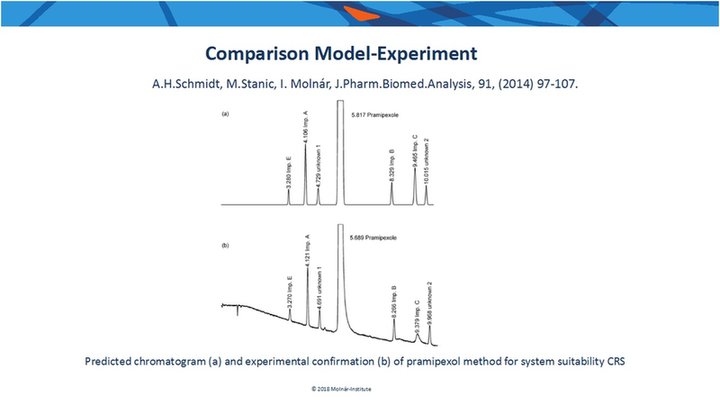

Fig.5. Predicted vs. experimental verification of the pramipexol method.

Conclusion

In summary, DryLab reliably models analytical methods, with good agreement between the predicted and experimental chromatograms. The Knowledge Management Document supported the continued pramipexol analysis using the redesigned robust method. Furthermore, researchers were able to modernize methods for use with the latest technology, both instruments and columns, as in another case with amlodipine. The use of Visual Chromatography Modeling is well received, with the ebastine method accepted at regulatory agencies in five countries. Finally, DryLab enables production labora-tories to readily fix methods at the end of their lifecycle to eliminate OoS results and improve productivity.

Contact information

For more information contact us at:

Molnár-Institute

E-Mail: info@molnar-institute.com

Register for free for our webcast on ‘’How to Manage Analytical Methods Across all Stages of their Life Cycle Using One Chromatographic Modeling Tool’’ at www.chromatographyonline.com