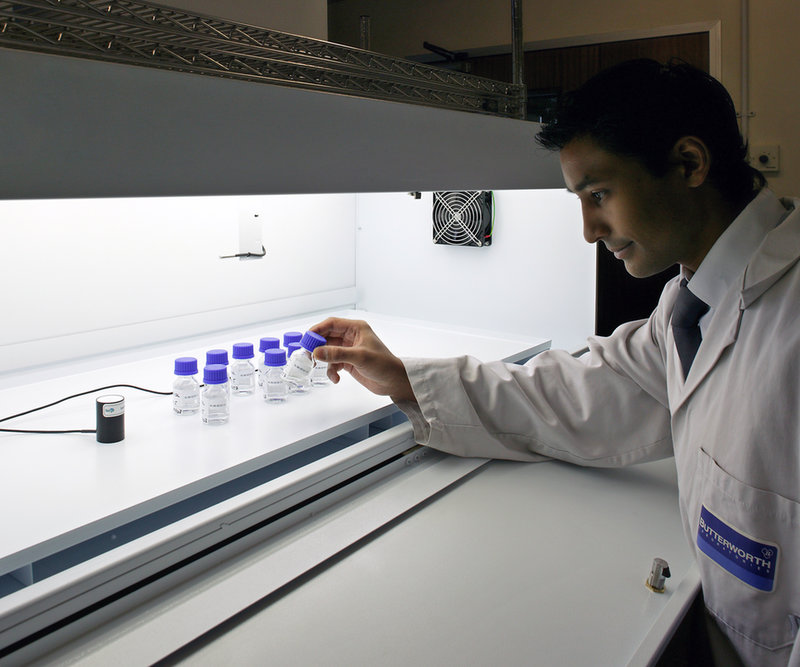

With over 40 years of analytical chemistry experience, Butterworth Laboratories are a UK based contract laboratory supporting the global pharmaceutical industry. Specialising in the quality control analysis of excipients, API, drug product, packaging and medical devices using recognised international standards, we also develop and validate methods to be used for quality control purposes using a wide range of techniques

Our regular inspections by the MHRA and FDA ensure that the services we provide are of the highest standard required by industry.

Quality ControlTesting

Outsourcing quality control (QC) testing of raw materials, intermediates, active pharmaceutical ingredients (API) and finished products can often prove to be a cost-effective option for many companies. Whether it’s lack of in-house facilities, cost of facility and equipment maintenance, meeting high workloads and short deadlines or simply to provide independent certification, we are able to help.

Our staff are experienced in the use of pharmacopoeial monographs, internationally published standards, client supplied or in-house developed methods.

Method Developmentand Validation

With our wealth of experience in QC testing we are able to bring together, both expert understanding of the technique employed and the practical working knowledge of our analysts to ensure successful method development robust enough for quality control purposes.

Following development of a method, it is vital that its performance is fully validated. Unless the client specifies otherwise, we validate methods to ICH guidelines as required by most regulatory authorities.

Stability Storageand Testing

The nature of Stability Studies makes them ideally suited to Outsourcing. Butterworth undertake testing of samples from Stability Studies for the complete set of study time points, or of just later phase time points.

Stability storage is outsourced to an approved facility, who are also able to handle any Microbiological testing requirements, whilst Photostability Services are handles in-house.

GLP and GCP

Butterworth Laboratories have been a member of the UK Good Laboratory Practice (GLP) Compliance Programme since 1989. As a result, data resulting from the conduct of non-clinical safety assessments is of internationally recognised quality.

Good Clinical Practice is a set of internationally recognised ethical and scientific quality requirements which must be observed for designing, conducting, recording and reporting clinical trials that involve the participation of human subjects.

Our GCP analytical services support the safety and quality assurance of Investigational Medicinal Products (IMP) and subsequently generated clinical sample analysis in compliance with UK and European legislation.

Quality ControlTesting

Outsourcing quality control (QC) testing of raw materials, intermediates, active pharmaceutical ingredients (API) and finished products can often prove to be a cost-effective option for many companies. Whether it’s lack of in-house facilities, cost of facility and equipment maintenance, meeting high workloads and short deadlines or simply to provide independent certification, we are able to help.

Our staff are experienced in the use of pharmacopoeial monographs, internationally published standards, client supplied or in-house developed methods.

Method Developmentand Validation

With our wealth of experience in QC testing we are able to bring together, both expert understanding of the technique employed and the practical working knowledge of our analysts to ensure successful method development robust enough for quality control purposes.

Following development of a method, it is vital that its performance is fully validated. Unless the client specifies otherwise, we validate methods to ICH guidelines as required by most regulatory authorities.

Stability Storageand Testing

The nature of Stability Studies makes them ideally suited to Outsourcing. Butterworth undertake testing of samples from Stability Studies for the complete set of study time points, or of just later phase time points.

Stability storage is outsourced to an approved facility, who are also able to handle any Microbiological testing requirements, whilst Photostability Services are handles in-house.

GLP and GCP

Butterworth Laboratories have been a member of the UK Good Laboratory Practice (GLP) Compliance Programme since 1989. As a result, data resulting from the conduct of non-clinical safety assessments is of internationally recognised quality.

Good Clinical Practice is a set of internationally recognised ethical and scientific quality requirements which must be observed for designing, conducting, recording and reporting clinical trials that involve the participation of human subjects.

Our GCP analytical services support the safety and quality assurance of Investigational Medicinal Products (IMP) and subsequently generated clinical sample analysis in compliance with UK and European legislation.