Powder compaction:

A REVOLUTIONARY

BENCHTOP R&D

TABLET PRESS

contact us

The STYL’One Nano is the most powerful and versatile benchtop press for R&D formulators. This tableting instrument brings features, previously reserved to premium compaction simulators, to every scientist with price/performance in mind.

How is your machine different from the existing presses from other suppliers?

R&D tablet presses can be divided in 2 categories: Small rotaries and single punch presses.

Single punch presses are ideal at the formulation stage: They are generally easy to operate, to clean and use small quantities of powder. They are also easily to be instrumented in order to generate accurate compression data. However, most suppliers use an old mechanical technology, called “eccentric”, to move the upper punch.

The base of the new STYL’One Nano is a unique system to drive the lower punch. This powerful technology is generally used in premium compaction simulators, equipment conventionally reserved to an “Elite”. This technology brings to the scientists the flexibility to drive the punches at high velocity to replicate the pre- and main compression of rotary tablet presses.

The choice of force or displacement driven studies matches the preferred working mode of all scientists.

« Let your powder speak

to you »

Does this mean that this piece of equipment is for tableting experts only? » No! «

S

TYL’One Nano is for every formulator in solid dosage forms with price /performance in mind. It can be used by nutritional supplement companies, academics, generic and prescription drugs manufacturers to suppliers of excipients.

The fundamental goal of a formulation scientist in tableting is, to make tablets. The tablets need to meet the dissolution and stability specifications and need to ultimately go smoothly through scale-up on commercial-size rotary presses.

With Nano:

- Plotting the tablet breaking force vs compression force has never been easier.

- The high level of automation makes the process seamless.

- Nano follows pre-defined protocols to study the adequate range of compression forces.

- Tablet breaking forces, measured by external hardness testers, can be automatically transferred back to STYL’One Nano.

- Screening a lot of different formulations in short time is now possible with Nano.

The formulator can focus on its primary assignment: Formulation. Another invaluable feature is the possibility to change process parameters of wet/dry granulation and to assess the effect on tablet properties and/or adjusting the right excipients to accommodate difficult API’s.

Does it integrate the latest USP monograph <1062> on tablet characterization? » YES! «

T

he USP <1062> monograph on tablet characterization is natively built into the software. Plotting Tabletability, Compactibility and Compressibility profiles is straightforward. Comparing plots on

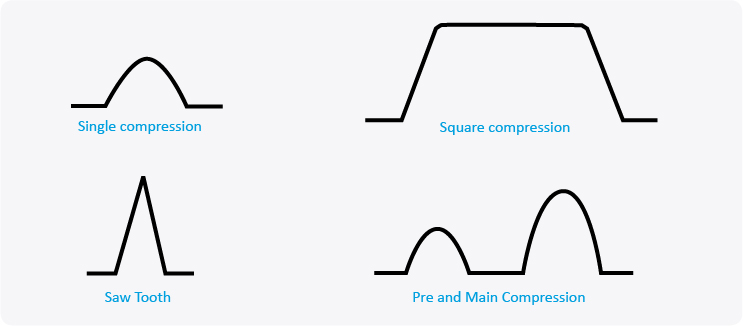

Nano software is intuitive. For the tech savvy scientist who want to dig deeper into material characterization, several punch displacement-time profiles are readily available (saw tooth, square, sinusoidal).

Is STYL’One Nano limited in its experiments and studies? » NO! «

The energy characterization (work of forces) for example is automatically calculated. The trace of ejection signals can be analyzed to detect any powder adhesion to the die bore in order to optimize the lubrication level. For day-to-day formulation works, the rotary press profile is the

profile of choice on Nano with pre and main compression. Running it at different rpm makes it simple to study the sensitivity of the formulations to strain rates. Tableting has never been so simple and so powerful at the same time.

Is STYL’One Nano easy to install and to move? »YES! «

The STYL’One Nano has been designed to be easy to install.

Just a 220V power supply and connection to the compressed air supply is needed. There will be

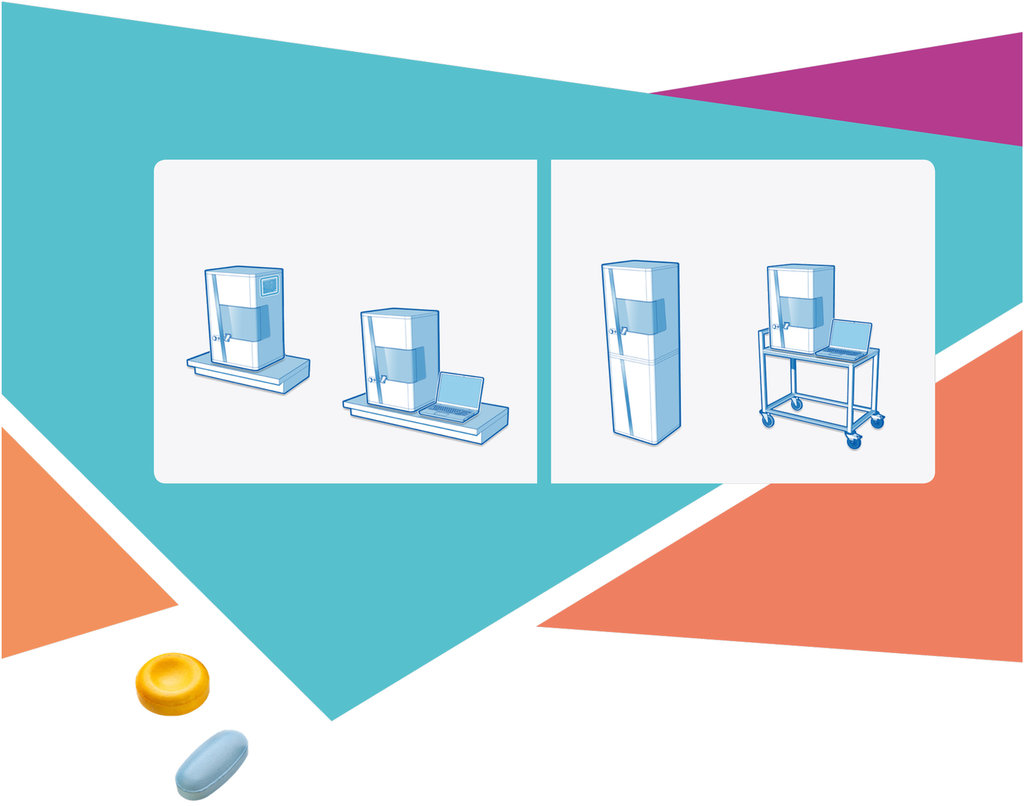

two versions available: One with a force display and one with a laptop computer to control, collect and analyze data with a powerful software

developed by Medelpharm. The STYL’One Nano is definitely smaller than compaction simulators and can be installed on a bench, on an optional pedestal or on a stainless steel cart. This way your R&D equipment can easily be moved from one room to another or just for cleaning the lab.

STYL'One Nano –

Have it the way you like!

Nano Smart

Nano No limit

Optional base stands

Which clientele is addressed for this type of Tablet press?

T

he Styl’One Nano has been built with all the technologies and learnings that Medelpharm has been gathering from 20 years of developing and manufacturing compaction simulator.

Therefore this press is a perfect instrument for API characterization

in early research as well as for the development of monolayer tablets for scientists in the industry. It is also ideal for universities or technology centres to develop new formulations powder characterization. It can also be utilized as a tool to teach future formulators/students the different aspects of tableting technology.