COMPANY INSIGHT

Sponsored by Wek-tec

Non-invasive up to 6 logs sterilization by Pulsed El. Fields or Intense Pulsed Light

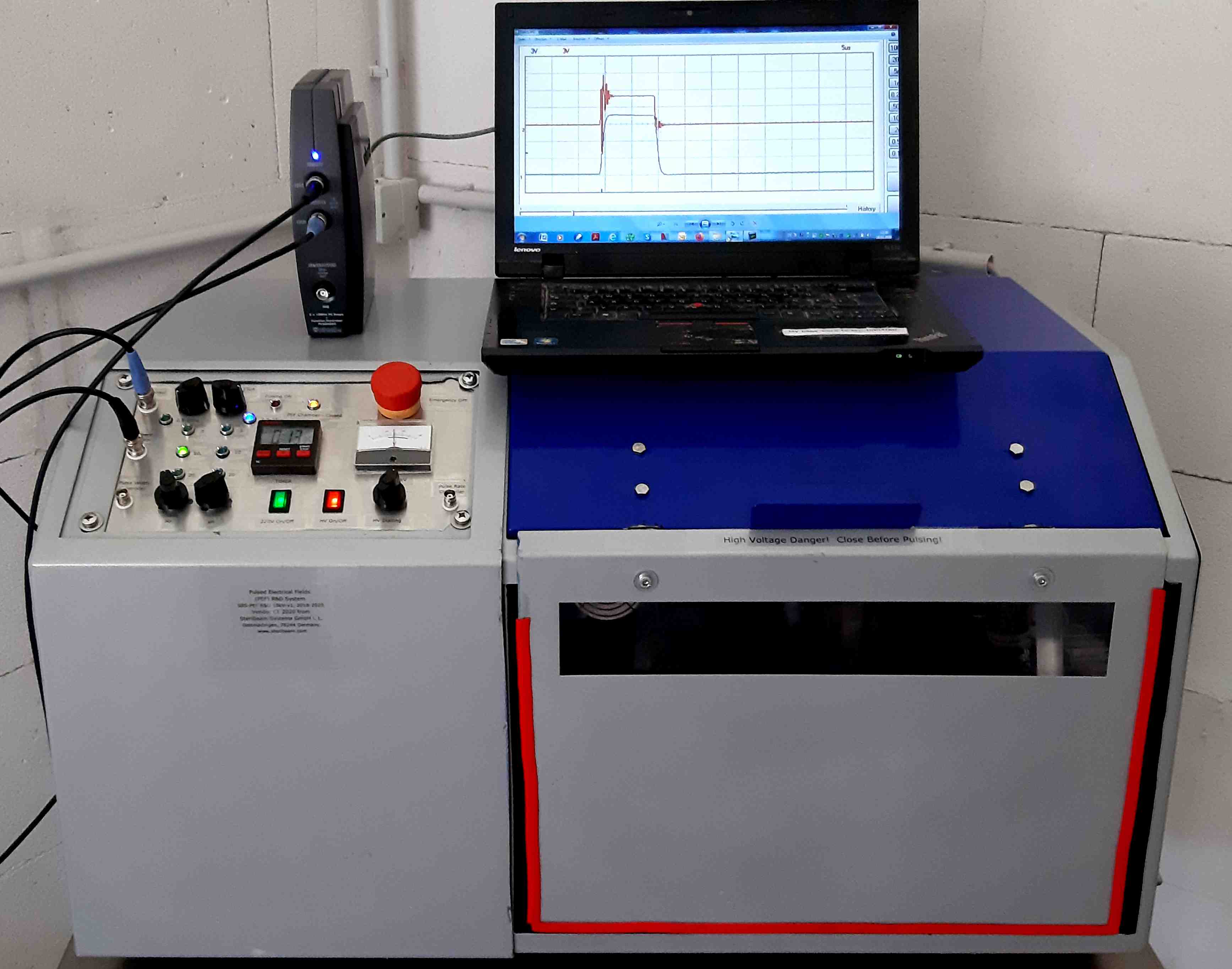

Because of a high efficiency at relatively low costs per sterilized items and because of leaving its original properties unchanged Pulsed Electrical Fields (PEF) systems are becoming the first choice for sterilizing pharmaceutical and cosmetic liquids, creams or for extracting vegetative colors just before its packaging. It always starts with finding optimal production parameters during on-line piloting with the type of a small production / R&D pilot system as presented below.

The great advantage of our pilot system is its very broad pulse parameters, simplicity and convenience in operations and the ability in just minutes to switch from processing liquids to processing creams or solids:

Configuration:

- can use the PEF chamber for solids & creams or a coax PEF chamber for liquids,

- For liquids- batch or direct flow processing.

Parameters:

- Pulse rates in Hz: 4, 20, 100, 500, variable 4-100;

- Pulse lengths in μs: 2,5, 5, 10, 50, variable 2,5-20;

- variable electrical fields in PEF chambers 5-50kV/cm;

- Selectable time for pulsing;

- 25kV power supply delivers up to 2kw or 3 kW (optional).

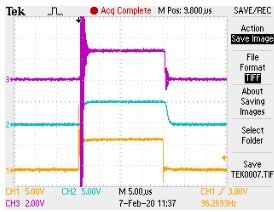

Pulse shapes:

- positive rectangular with ca. 1 µs fronts and tails;

- Flatness: ca. 2% at 5µs, ca.10% at 25µs;

- pulse controls: by a digital scope (provided).

For more details on this PEF system please click the photo.

Wek-tec e. K. looks for an industrial partner to ramp it up on the market.

While the basic PEF process is known since decades as stretching bacterium till its eruption by sharp pulsing electrical fields, each practical case, aside of already known for clear juices, requires a process development work for finding optimal PEF pulse parameters.

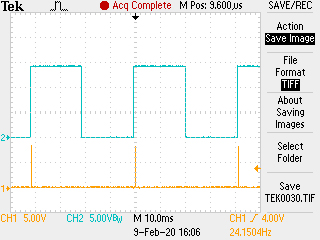

Specifically important to have a broad selection of sharp rectangular pulses with various durations (left) and frequencies (right)

More is in “Basics of the PEF technology”.

Specifically important to have a broad selection of sharp rectangular pulses with various durations (left) and frequencies (right)

More is in “Basics of the PEF technology”.

For finding optimal sterilization parameters at your R&D lab we offer our multiparameter bench-top PEF system with two PEF chambers (left). Such systems are used in universities and industrial labs. For smaller tasks at universities, we offer low budget simple PEF device for liquids with ca. 5µs pulsing (right):

Sterilizing surfaces & pharmaceutical liquids in clear vials or packs with our Intense Pulsed UV Light (IPL) systems and our pulse energy chart below:

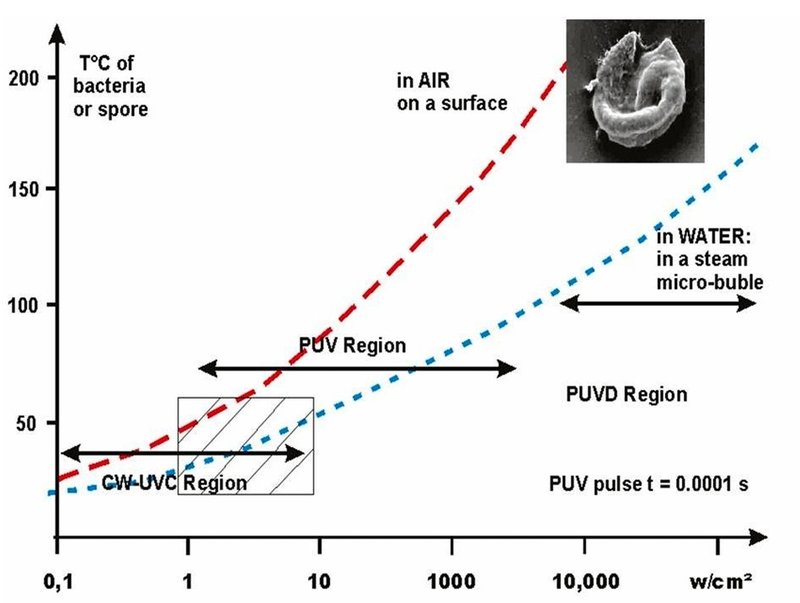

3 basic regions for the Pulsed UV Light for single pulse power in w/cm² at sample levels.

Regions 1 and 2 are to sterilize through deactivating DNA of microorganisms, where the first region is almost identical to continuous UVC light.

The region 2- is for accelerated PUV destruction of DNA and #3 – allows to UV resistant spores of B. Pumilos.

Pfizer, Baxter and other pharma companies are interested in those for sterilizing transparent liquids in glass vials or in transparent plastic bags.

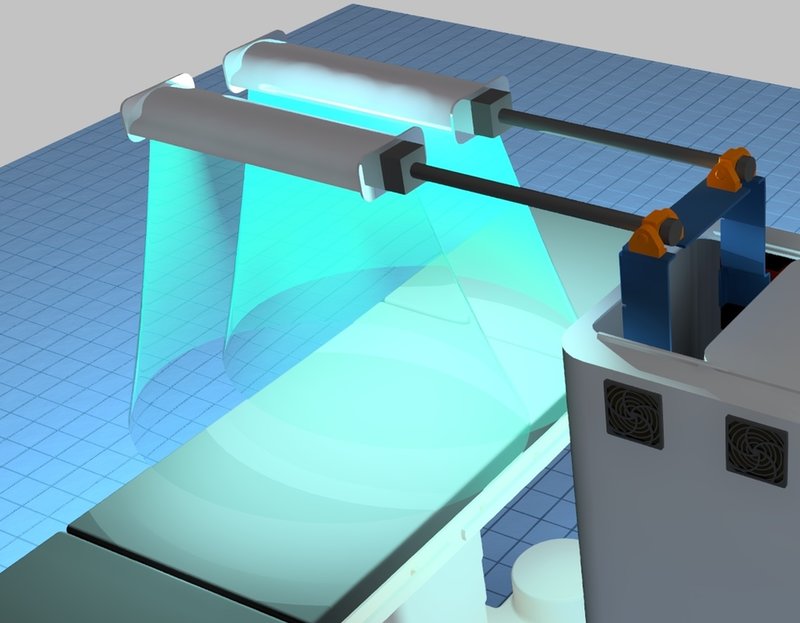

To reach your PL objectives we offer three bench top R&D systems with Intense Pulsed (UV) Light lamps and broad pulsing parameters as the one on the left.

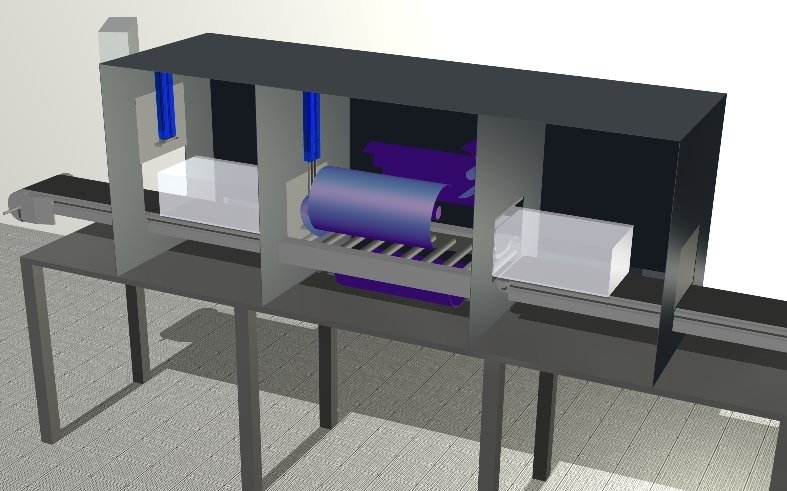

Our fully automatic like this and two simpler R&D PUV systems, often customized, were used at various universities to generate data for many publications referenced Worldwide.

To reach your PL objectives we offer three bench top R&D systems with Intense Pulsed (UV) Light lamps and broad pulsing parameters as the one above.

Our fully automatic like this and two simpler R&D PUV systems, often customized, were used at various universities to generate data for many publications referenced Worldwide.

The configuration of this R&D systems allows scaling it up to production PL tunnels shown below. More on our offers for available and suggested UV system please see our brochures connected to two images below.

Wek-tec e. K. looks for an industrial partner to ramp it up on the market.

Please, send us your requirements using our contact form

UV sanitation and/or nutrient modifications of powdered products.

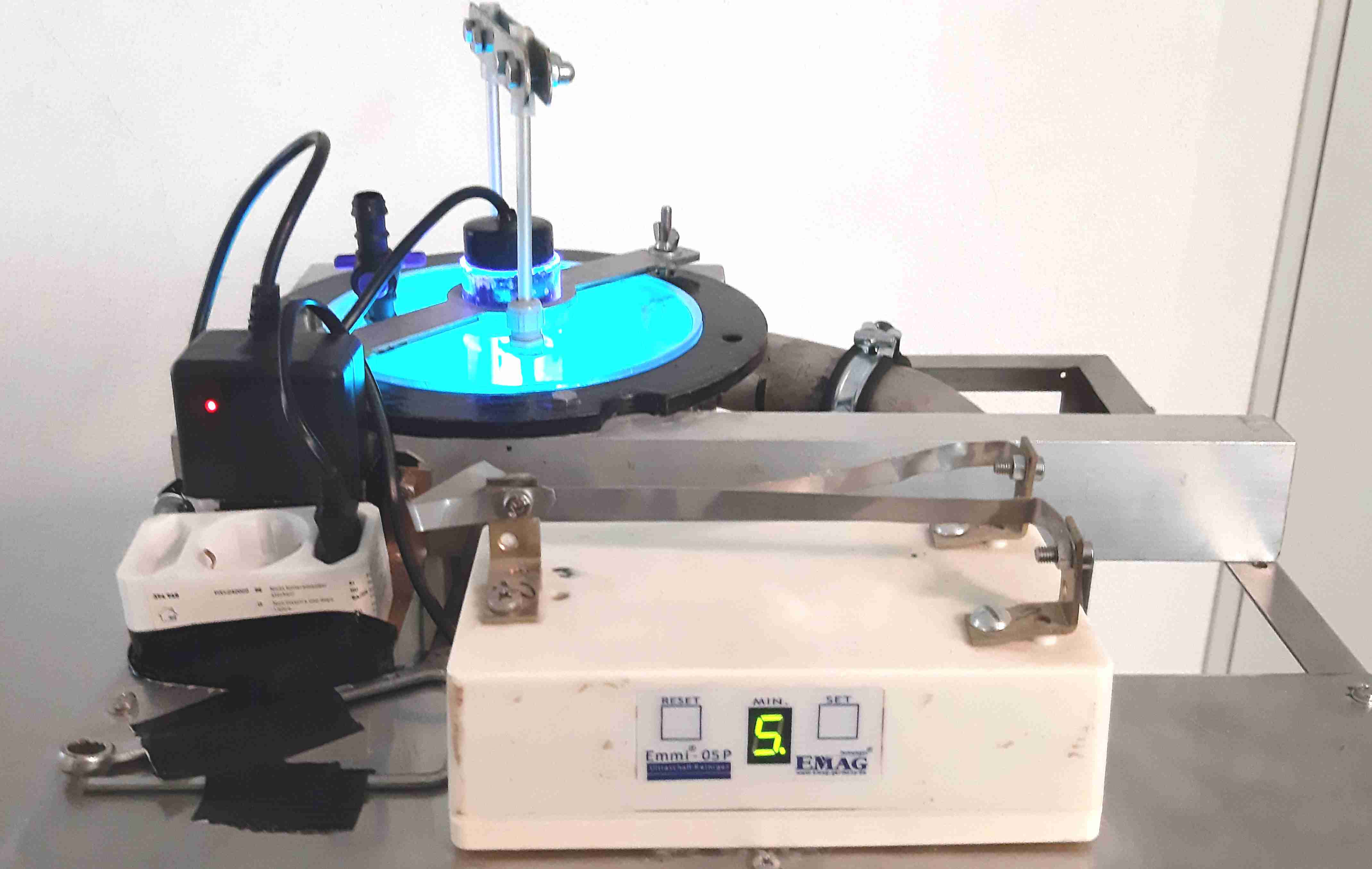

This lab R&D Vortex type system moves a nutrition powder inside a cylinder around a long UV lamp in its centre by a forced Nitrogen rich air flow for 2 purposes:

1: to sanitize powder particles with UVC lamp lines,

2: to modify powder nutrient properties with UVC, UVB or UVA lines, directly or filtered. E.g.: increasing the vitamin D3 content by 100´s in mushroom powders.