Company Insight

Sponsored by wek-tec

wek-tec offers two non-invasive and up to absolute sterilization methods:

Main image credit:

#1: Intense UV pulses fully sterilize clear-packed clear liquids.

It was proven on our PL system by Baxter Corp. with UV resistant spores of B. Pumilos:

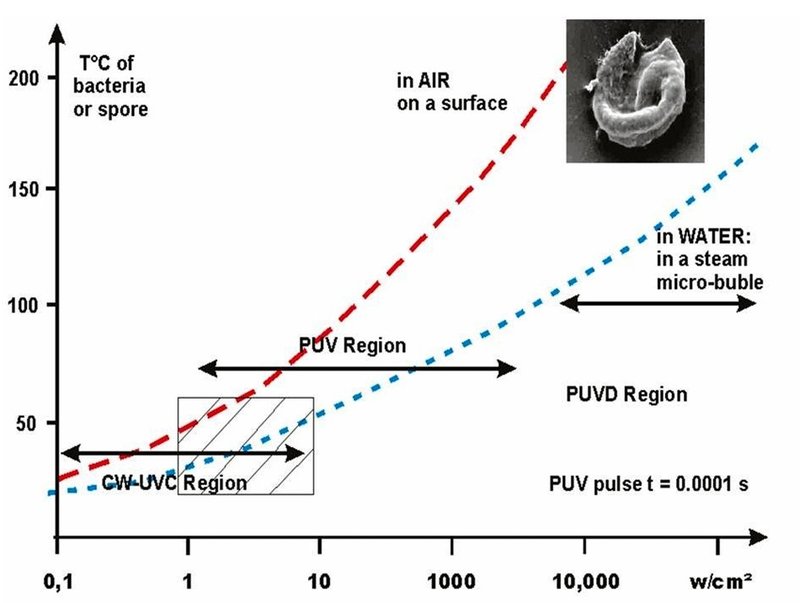

Clarifications to the energy chart below:

the effectiveness of Pulsed UV light increases with its power from identical to the continuous UVC light by low pressure Mercury vapor lamps to turning on accelerated DNA damages possible only for the intense UV pulses.

Further right on the power scale in w/cm² starts the PUVD region where the applied power of UV and also of the visible light pulses physically disintegrate bacteria and spores.

For this process to happen, UV and light pulses have to be very short, intense and rapid.

It makes it possible to sterilize vaccines in vials.

wek-tec offers to check sterilization of your products with our PUV R&D systems:

Data obtained during evaluation of your cases will allow to construct full-scale production PL sterilization tunnels for vials or for other use.

This method and PUV tunnel designs are wek-tec`s IP.

#2: non-invasive sterilization by Strong Pulsed Electrical Fields

Of various liquids and creams with our multi-parameter PEF pilot system available for custom process development supported by our local bio-lab:

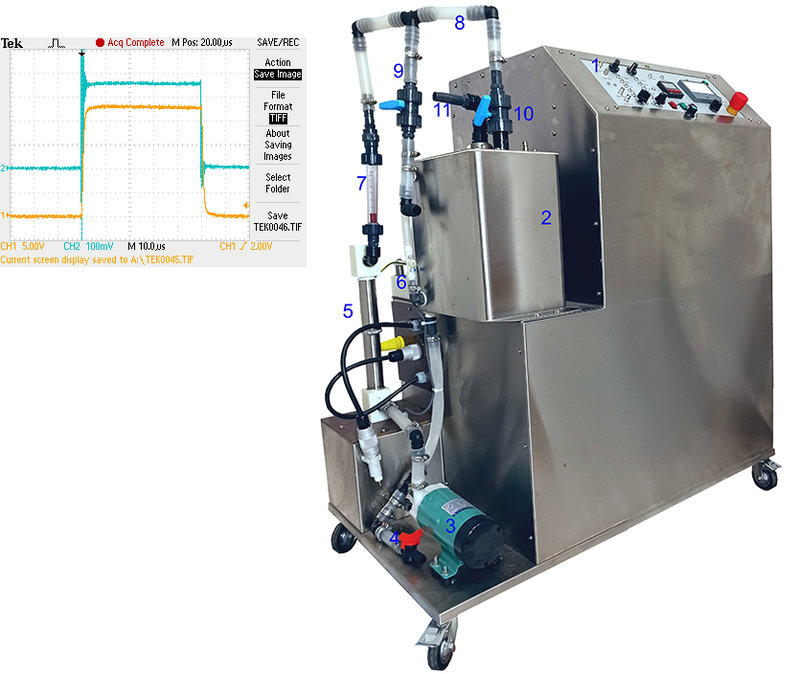

The PEF pilot has the industry broadest changeable pulse parameters, operational convenience and safety:

- Pulse rates from 4Hz to 500Hz;

- Pulse are positive rectangular;

- Pulse lengths from 2µs to 50µs;

- Pulse fronts are ca. 1 µs,

- Pulse flatness ca. 5%;

- Electric fields 5kV/cm to 50kV/cm;

- selectable pulsing time from 1s to 9h;

- 25kV 2kW pulser, up to 10kW options;

- overcurrent protection is build-in;

- scope is outside or build-in;

- in R&D changing from flat to coax chambers: 1min.;

- convenient, simple to maintain, safe.

PEF sterilizes by stretching bacteria up to its ruptures with electrical fields 20-50kV/cm delivered by sharp square pulses as shown below for 25kV 50µs pulses:

More on process details is here.

PEF pilot brochure available here.

The PEF pilot can be delivered in one of two versions:

1: for R&D: 1

x PEF chamber for solids & creams and 1x coax PEF chamber for liquids;

2: for pilot production:

two in line coaxial chambers at same or different optimally enhanced pulsing using batch or direct flow through processing.

Both have easy to use reliable analogue control panel:

This PEF method and pilot designs are wek-tec`s IP.

The new promising method from wek-tec for UV sanitation or nutrient modifications of powders:

This lab R&D Vortex type system shown below provides physically only possible full UV exposure of each powder particle by moving powders in the Nitrogen enriched turbulent air “vortex” flow in a cylindrical chamber around a long UV lamp in its centre. It can be used for either:

- to sanitize powder particles with UVC lamp lines.

- with UVC, UVB or UVA to modify powder nutrient properties.

Note: some powders have physical limitations for higher than 2 logs reductions with UV light.

Our UV tunnel for powders has been designed for up to 100kg/h for a flow-through sanitation or powders photo-chemical modifications. It is for further adjustments in line with per data from evaluation of customers powder on our Vortex.

This method and the tunnel design are IP of wek-tec.

Please, send us your requirements along with your full affiliation via e-mail at info@wek-tec.de

wek-tec e. K. looks for an industrial partner to mutually benefit from our IP.

Contact information

wek-tec e. K.

Kronenstr.3

D-78244 Gottmadingen

Tel.: +49 (0)17270844 37

Email: info@wek-tec.de

Web: www.wek-tec.de